Description

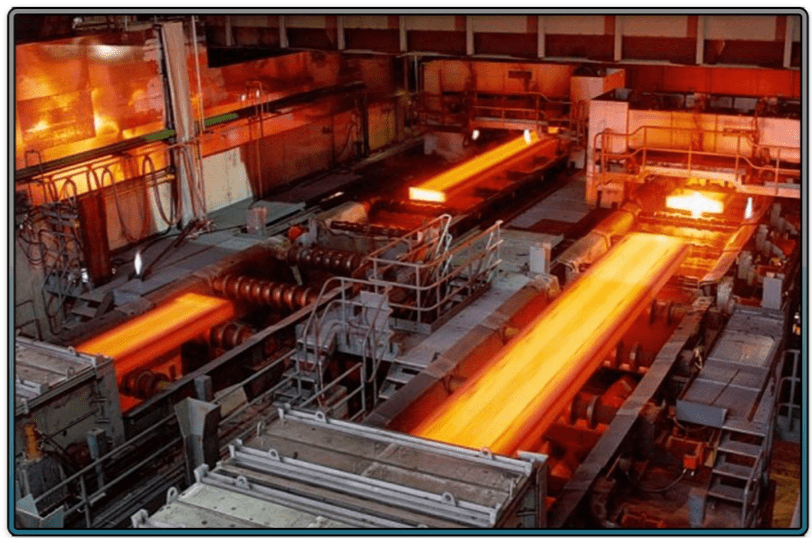

Sandblasting sand is one of the most effective and widely used abrasives in industrial surface treatment. It is specially designed for cleaning, removing rust or old paint, and preparing surfaces for painting, coating, or assembly. Whether you’re in the automotive, metalworking, construction, or marine industry, sandblasting sand ensures precision and high-quality surface results.

Key Advantages of Using Sandblasting Sand

1. Effective Cleaning

Quickly removes rust, old paint, scale, and surface contaminants. Ideal for both small components and large industrial parts.

2. Surface Preparation

Creates the optimal surface roughness needed for strong adhesion of paints, coatings, and adhesives.

3. Improved Coating Durability

By preparing the surface thoroughly, it enhances the performance and life span of coatings, reducing the risk of flaking or peeling.

4. Cost-Effective

Using high-quality abrasives minimizes rework and maintenance costs by ensuring better first-time results.

Industrial Applications

Automotive Industry

Component cleaning before painting or mechanical assembly.

Metal Industries

Surface treatment and cleaning before applying paint or protective coatings.

Marine Industry

Efficient removal of rust and salt deposits from ship hulls and oil platforms.

Construction Sector

Prepares concrete and steel surfaces before applying protective layers, such as epoxy or waterproof coatings.

About Sandblasting Sand

Sandblasting sand is propelled at high speed to clean and roughen surfaces. It effectively strips away coatings, contaminants, and corrosion, leaving the surface ready for further processing. It is essential for achieving professional and long-lasting finishes in various industries.

Types of Sandblasting Sand We Offer

1. Silica Sand

-

Very hard and sharp

-

Perfect for cleaning tough metal surfaces

-

Ideal for aggressive blasting jobs

2. Copper Slag (Grit)

-

High density, low dust emission

-

Contains less than 1% free silica, making it safe for industrial environments

-

Suitable for sensitive surfaces

3. Olivine

-

Silica-free and environmentally friendly

-

Highly recyclable

-

Suitable for delicate or soft surfaces

Available Packaging

We offer our sandblasting sand in multiple packaging options to suit your project size—bulk bags, 25 kg sacks, or custom quantities upon request.

Need Help Choosing the Right Type?

Our experts are ready to help you choose the best abrasive for your specific application. Contact us for technical advice or a bulk purchase quote.

Why Choose Our Abrasives?

Our blasting media is manufactured under strict quality standards to ensure high purity and consistent grain structure. It is designed for optimal performance with both manual and automated blasting systems.

Whether you’re restoring antique metalwork or prepping massive steel structures, our abrasives deliver efficient cutting action without compromising safety or surface integrity.

Health & Environmental Benefits

Our low-silica and non-toxic abrasive materials reduce airborne dust exposure and help maintain safer work environments. They are suitable for open-space and enclosed blasting operations, in compliance with international safety standards.

Technical Support and Custom Orders

We provide expert consultation to help you select the best abrasive for your specific job. Custom grain sizes, blending, and packaging are available upon request to meet your technical and operational needs.

Reviews

There are no reviews yet.